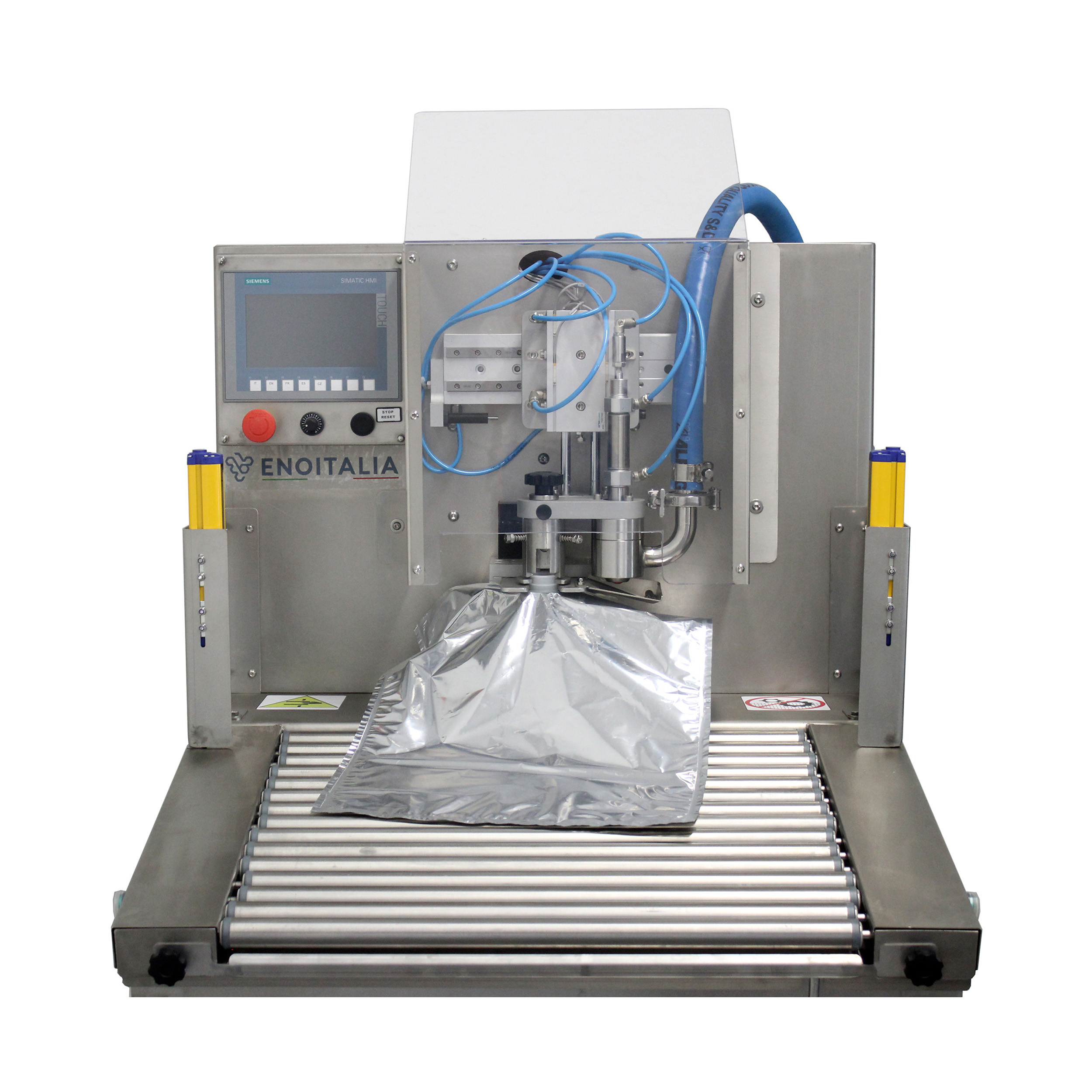

Automatic filling machine for filling single bags. Prepared for filling wine, oil, food liquids such as creams and sauces with solids, industrial liquids (soaps, lubricating oils).

The machine is completely built in stainless steel, with a wide roller surface for the sliding of the containers. The filling cycle is completely automatic: the machine carries out all the operations of opening, closing, vacuum, saturation with inert gas, filling. Under vacuum, the operator only has to position the bag and check the progress of the various operations.

The standard equipment of self-priming volumetric pumps with rubber impeller guarantees: high flow rate; possibility of priming from any container; steady flow; anti-pressure by-pass valve; total drain valve for emptying the filling circuit. The possibility of installing special pneumatic adapters allows countless types of caps to work with the machine, in addition to the standard VITOP.

SIMPLICITY: The machine is completely built in stainless steel, with a large roller surface for sliding the containers. The filling cycle is completely automatic: the machine performs all the operations of opening, closing, vacuum, saturation with inert gas, filling. In addition, a special closing system keeps the container sealed during all the filling phases, reducing the oxidation and contamination of the filled product. The operator only has to position the bag and check the progress of the various operations. The SIEMENS touch screen control panel allows you to manage the machine in just a few moments both in filling operations and in washing and sanitizing operations. The standard equipment of self-priming volumetric pumps with rubber impeller guarantees: high flow; possibility to prime from any container; steady flow; anti-pressure by-pass valve; total drain valve for emptying the filling circuit. The possibility of installing special pneumatic adapters allows you to work with the machine countless types of caps, in addition to the VITOP supplied as standard

PRECISION: the control panel equipped with SIEMENS PLC allows you to manage all the filling phases, adapting the machinery to any type of liquid treated (wine, fruit juices, oil, water, creams, etc.). Possibility to carry out 3 different types of AUTOTUNING regulation, macro error (pulses / liter), micro error (addition or subtraction of the centiliters). Repeatability of volumes with error of 0.5-0.2% (varies according to the type of sensor installed). Possibility of installing electromagnetic or induction flow sensors

SPEED: all operations carried out automatically by the filler are set by the operator according to their needs: vacuum time, gas injection times, filling speed, opening and closing speed of the bag. The possibility to choose between two types of pumps with different flow rates and to install a speed variator allows you to easily reach all the desired capacity objectives.

SAFETY AND CLEANING: total protection in the use of the machinery with the presence of safety barriers and travel buttons. The machine is equipped with automatic programs for sanitizing both with detergents and with 110 ° C steam (requires the appropriate kit). A stainless steel tap is supplied as standard for the washing CIP circuit. The anti-drip total closure valve guarantees the escape of liquids at the end of the filling. The VACUUM filling system (bottom container closure system), in addition to minimizing the risks of contamination of the filled products, facilitates installation and format change, avoiding adjustments to the filling head height. Possibility to install 10 “or 30” filter housing (separate from the machine body), for final sterilization safety before filling.

RELIABILITY: Use of SIEMENS electrical and pneumatic components of primary brands, always available in our warehouses; possibility of carrying out remote assistance interventions upon customer request.

OTHER ADVANTAGES: adjustable support for the cardboard box; large support surface with sliding rollers, with drip tray with total drain; 7 “display; multilingual programming (English, French, German, Spanish, Russian) selectable from the front panel; oiless filter for air circuit; stainless steel control panel; pneumatic and electronic system easily accessible and equipped with lighting; POUCH and STAND-UP filling.

MODELS

Cod.9400 – BB30 with pump capacity 4500 lt/h

Cod.9401 – BB30 with pump capacity 9300 lt/h

| Model | Connection | Capacity 3 lt/h | Capacity 5 lt/h | Capacity 10 lt/h | Capacity 20 lt/h | Power Hp (Kw) | Dimension (mm) | Weight |

| 9400 | TRICLOVER 1,5” | 380 | 240 | 210 | 140 | 1,5 (1,1) | 800x1000x1500 | 140 Kg |

| 9401 | TRICLOVER 1,5” | 450 | 300 | 240 | 180 | 2 (1,5) | 800x1000x1500 | 144 Kg |